Production program

Production program

Investment casting technology is based on a lost wax model..

The actual casting process with this method consists of several basic processes:

Production of wax patterns

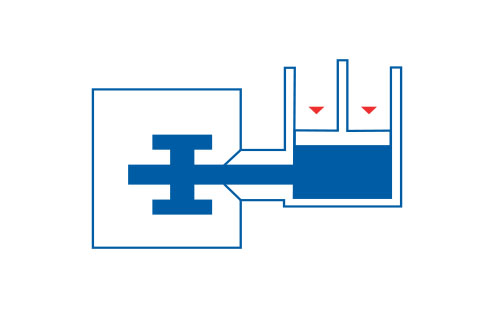

Semi-plastic wax is injected into the mold under pressure.

After solidification, the wax model is removed from the mold.

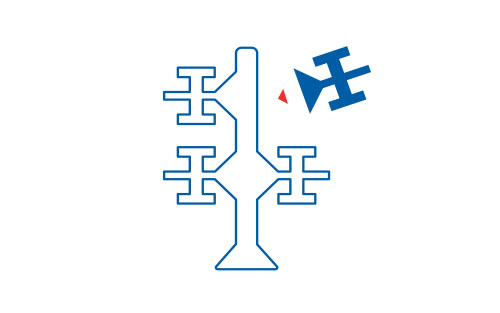

Cluster assembly

Wax models are glued to different types of central sprue and clusters are created.

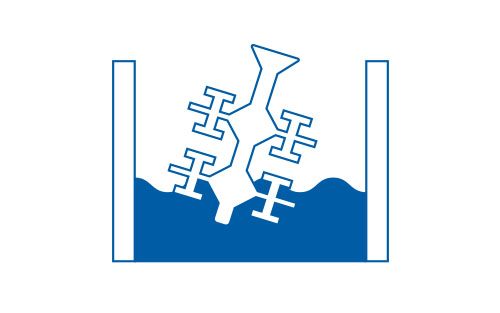

Dipping

The trees are soaked in a slurry after they have been degreased and dried.

Facing

In the gravity shooter, several layers of sand are applied to the trees, in order to create a sufficiently ceramic shell.

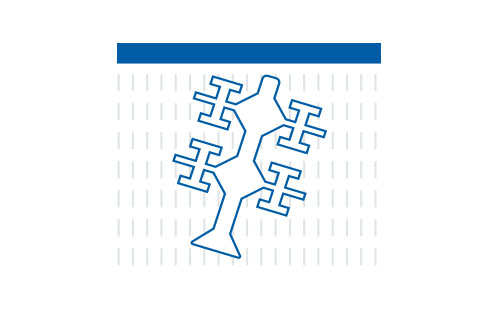

Melting

After drying the ceramic shell, wax is melted from its inside.

Annealing

The shell is annealed in a furnace at temperatures of about 1000 °C.

Casting

The molten metal is poured into the annealed shells.

Finishing

Castings are cut from trees.Sprue are grinded according to customer requirements.

Checking

The chemical composition of the castings is controlled at each melting process. Visual inspection is performed before each shipment. Size and dimension checks are always carried out when new castings are introduced into production or as required by the customer.

What we produce

Our products – Investment castings